AIPIA Congress Update: The key to DPP: How NFC can unlock seamless compliance | 17-06-2025 |

Identiv, one of the platinum sponsors at the imminent AIPIA & AWA Smart Packaging World Congress 2025, is taking a leading role in the preparations for Digital Product Passports (DPPs). Their forward-thinking approach to smart packaging will be a key topic of discussion at the Congress, taking place June 23–24 in Amsterdam, the Netherlands.

The following article by Identiv, ST Microelectronics and NFC Forum is an excellent introduction to how NFC Smart Packaging will be at the forefront of DPP development:

A DPP serves as a digital bridge between a physical product and its online “twin.” This provides comprehensive data about the product’s design, manufacturing, material makeup, maintenance, and recyclability. As part of the EU’s Ecodesign for Sustainable Products Regulation (ESPR), DPPs aim to enhance transparency, sustainability, and circularity across various industries.

DPPs aren’t entirely new in concept. Many brands already link physical products to digital information. Think QR codes that launch loyalty programs or display product details. The difference? DPPs will be mandatory under EU regulations, meaning companies selling into the EU must be planning now for how they will comply, and specifically, how they will make their DPPs and DPP data accessible on their products and packaging. The need for real-time, tap-and-go access to this data demands a solution that is not only reliable but already in the hands of billions of consumers.

Enter NFC technology: With a smartphone most people probably have an NFC-capable scanner in their pocket. After roughly a decade’s worth of standards development and industry advancement, NFC is one of the most widely adopted wireless communications technologies. And most users don’t know they’re using it. Roughly 98% of smartphones have built-in NFC. In 2022, estimates were that 3 billion NFC-enabled devices existed worldwide and at 85% owners had used the NFC feature.

Naturally, product manufacturers, packagers, and resellers have seen NFC as a critical technology for everything from supply chain management to customer engagement. A next logical step would be to use NFC for DPP compliance. Central to the DPP initiative is better educating consumers about and authenticating the products they buy. Other goals include sustainability attributes and ways to better manage their useful lifecycles — all the way through to reuse or recycling. What better way to communicate that information to consumers than through the product “scanners” they already own?

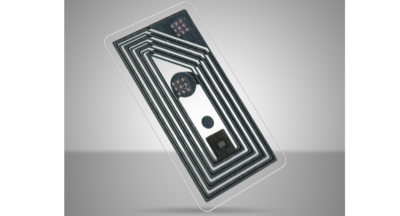

NFC is built for DPP compliance: NFC already has a proven track record in smart packaging. A decade ago, the first “smart bottles” of Johnnie Walker whiskey had NFC radio tags designed into their labels. Consumers could scan the bottle, make sure it was authentic, find recipes, and even determine if it had been tampered with. Since then, technology companies have created NFC inlays — integrated Internet of Things (IoT) solutions with differing microchips, antenna designs, and form factors — to work with various types of packaging. Such inlays can be affixed to products, like stickers, or manufactured into the product or packaging itself.

There are several reasons NFC is an ideal data carrier for DPP requirements. Firstly, among the targeted DPP users (consumers as well as supply chain workers), NFC is readily available in the smartphones so many people carry. No other DPP carrier technology enabling a truly wireless connection between a product and its DPP — is already in so many pockets.

Next, NFC offers technology longevity. Whether designed into the packaging or the product itself, NFC inlays are built to last. And considering a DPP is meant to follow the products throughout their lifecycle, that could be years. Some of the earliest product categories that will need to be DPP-compliant are large batteries and apparel. Both of these would need the ability to access their DPPs for a long time. In fact, in the case of apparel, with its robust secondary market of used and vintage clothes, a persistent DPP is key to maintaining a chain of authenticity and sustainability.

Additionally NFC can work where connectivity doesn’t. NFC inlays have their own data storage, meaning the DPP can exist online and on the product or packaging itself. Therefore, in places where internet connectivity is patchy or non-existent, users could still make the connection between their smartphone and an NFC-enabled product and access the DPP. This is crucial in facilities that process or recycle products at scale, like waste disposal sites, which often don’t have network connectivity.

NFC is DPP-ready and well-positioned for future-proofing. The NFC Forum, the global standards body for NFC technology, earlier this year published new candidate specifications aimed at enhancing the user experience and standardizing the way DPP information is exchanged through the NFC Data Exchange Format (NDEF) – a standardized data format that enables seamless communication and off-line data storage across NFC-enabled devices. These updates are expected to be approved by Q2 2025, establishing a unified approach for secure data retrieval even without network connectivity.

In short, NFC technology offers a robust solution for implementing DPPs in smart packaging and product design. It allows companies to align with regulatory requirements while enhancing transparency, traceability, and consumer trust — all with a technology most people already use. As companies plan for DPP compliance, the solution may already be in their hands.

Authored by Klaus Simonmeyer, VP of Strategic Accounts EMEA, Identiv; Jean-Rémi Ruiz, Standardization & Lobbying Manager, STMicroelectronics; and Mike McCamon, Executive Director, NFC Forum the full article first appeared in the Label & Narrow Web journal.

REGISTER TODAY. IT'S NOT TOO LATE